Processing capacity: 12-1000 t/h

Discharge opening: 3-60 mm

Feeding size: 35-300 mm

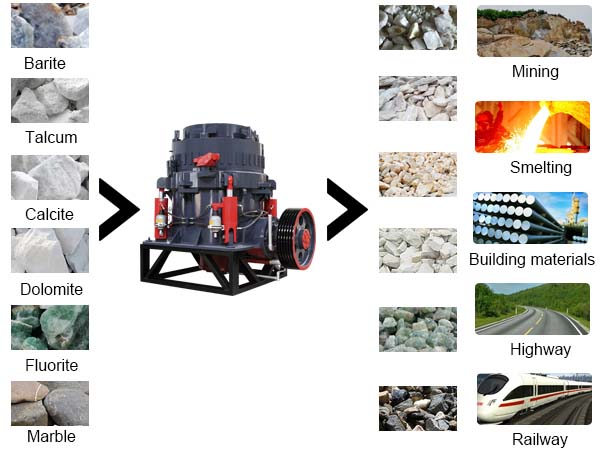

Applied material: barite, marble, talcum, calcite, dolomite, fluorite, kaoline, coal, gypsum.

This series of crusher machine is divided into three types, namely coarse cone crusher, medium cone crusher and fine cone crusher, and the standard type is suitable for medium crushing; the medium type and the short-headed type is suitable for fine crushing, so that the customers can choose different types according specific need.

This cone crusher is suitable for crushing various kinds of ores and rocks with medium over hardness and it has the features of reliable structure, high production efficiency, convenient adjustment and economic use. It adopts two sealing means: dry oil and water to separate stone powders and lubrication grease, thus ensuring reliable work of the machine.

Our cone crushers are suitable for a wide range of applications, including quarrying, mining and tunneling. End products include aggregates for concrete, asphalt and railway ballast. Designed to operate across a wide range of duties, the Hongxing cone can be fitted with any one of seven different cavity profiles from extra coarse through to extra fine, giving this machine outstanding versatility.

When cone crusher begins to work, the electro motor drives the eccentric sleeve through the spring coupling, drive shaft and a pair of angle gear, so that the crushing wall of cone crusher gets close to and then gets away from the surface of the rolling mortar wall fixed on the adjusting sleeve, and the ores inside the crushing chamber will be constantly impacted, squeezed and bent to be crushed.

| Specification | Model | Diameter of large end of crushing cone (mm) |

Max.feeding size(mm) |

Width of discharge opening (mm) |

Processing capacity (t/h) |

Motor power (kw) |

Total weight (t) |

Dimensions (L×W×H) (mm) |

| Φ600 | PYB600 | 600 | 65 | 12-25 | 40 | 8P 30 | 5 | 2234×1370×1675 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | 2234×1370×1675 | |||

| Φ900 | PYB900 | 900 | 115 | 15-50 | 50-90 | 8P 55 | 11.2 | 2692×1640×2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | 2692×1640×2350 | |||

| PYD900 | 50 | 3-13 | 15-50 | 11.3 | 2692×1640×2350 | |||

| Φ1200 | PYB1200 | 1200 | 145 | 20-50 | 110-168 | 8P 110 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 100 | 8-25 | 42-135 | 25 | 2790×1878×2844 | |||

| PYD1200 | 50 | 3-15 | 18-105 | 25.3 | 2790×1878×2844 | |||

| Φ1750 | PYB1750 | 1750 | 215 | 25-50 | 180-360 | 8P 160 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 185 | 10-30 | 80-210 | 50.3 | 3910×2894×3809 | |||

| PYD1750 | 85 | 5-13 | 60-180 | 50.2 | 3910×2894×3809 | |||

| Φ2200 | PYB2200 | 2200 | 300 | 30-60 | 420-700 | 8P 280-260 | 80 | 4622×3302×4470 |

| PYZ2200 | 230 | 10-30 | 130-410 | 80 | 4622×3302×4470 | |||

| PYD2200 | 100 | 5-15 | 80-200 | 81.4 | 4622×3302×4470 |

Our sales team is available to respond to any queries you might have on HXJQ. Get in touch using the details below:

No.8, Tanxiang Road, Zhengzhou, Henan, China.

0086-371-67833161